Understanding Branding Techniques and Processes

Not sure what branding method works best for your logo?

In an era where markets are flooded with endless choices and digital platforms amplify consumer voices, the power of branding has never been more pivotal. Branding is no longer just about creating a distinctive name or a striking logo; it's about crafting a unique identity that resonates deeply with customers and stands out in a crowded marketplace. It's a complex blend of art, strategy, and psychology that shapes perceptions, builds emotional connections, and drives customer loyalty.

In today's hyper-connected world, a strong brand can be the decisive factor between thriving success and unnoticed obscurity. It's the brand that tells a story, creates an experience, and promises a certain quality. This narrative is what people remember, share, and come back to. As Jeff Bezos famously said, “Your brand is what other people say about you when you’re not in the room.” It's the perception that exists in the minds of your audience about your products, services, and overall presence in the market.

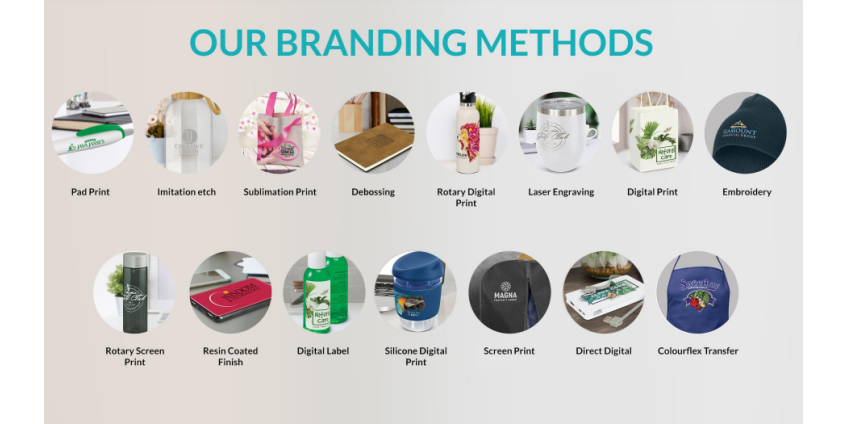

This blog delves into the multifaceted world of branding, exploring a variety of branding methods that businesses use to carve their niche and leave a lasting impression. From traditional techniques like pad printing and screen printing to modern approaches like digital printing and laser engraving, each method offers unique benefits and caters to different needs. Understanding these methods is crucial for any business aiming to establish a strong brand identity and connect effectively with its audience.

Join us as we embark on this journey through the art of branding, unpacking the intricacies of each method and discovering how they can elevate a brand’s presence in the competitive marketplace of today.

PAD PRINT

A laser-etched printing plate is used to transfer an image onto a product via a silicone pad. This process is highly regarded for its popularity and cost-effectiveness as a branding method. Key features include:

- The ability to print effectively on surfaces that are curved or irregular.

- The production of sharp and clear images, capturing fine details with precision.

- The capability to print in multiple colors in a single pass, ensuring precise alignment and registration of colors.

This method's combination of affordability, versatility, and high-quality output makes it a favored choice in branding techniques.

IMITATION ETCH

This technique employs a unique pad printing ink to create an etch-like appearance on glass, offering a cost-effective and convenient substitute for traditional etching. It is capable of branding on products with curved or uneven surfaces, resulting in a subtle finish that enhances the perceived value of the product.

SCREEN PRINT

In this method, ink is pushed through a finely woven mesh screen, making it perfect for items with flat surfaces. It allows for expansive print areas and the ability to apply up to five colors on most products with precise color alignment. The inks used in screen printing typically dry rapidly, enabling the products to be ready for immediate shipment post-printing.

ROTARY SCREEN PRINT

Ink is pressed through a finely meshed screen in this process. Rotary Screen Printing is particularly suited for cylindrical objects, offering extensive branding space. It allows printing of up to five colors on a majority of products, ensuring precise color alignment. The inks used in this method dry quickly, facilitating the immediate shipment of products post-printing.

LASER ENGRAVING

This method involves a laser to permanently engrave artwork directly onto the product's surface. It is often regarded as having a higher perceived value compared to other branding methods. It offers the advantage of large areas for branding and allows the product to be ready for shipping immediately after engraving. This technique can also accommodate variable data, such as names. Additionally, the engraving finish varies depending on the material used, making pre-production samples a recommended step.

DEBOSSING

Often called 'Blind' debossing, this technique is a permanent branding method that enhances the perceived value of the product. It involves pressing a heated custom metal plate onto the product, creating an indented impression of the artwork. The product is ready for shipment right after this branding process. Thermo debossing, which applies extra heat, creates a distinctive and visually appealing two-tone finish on select products.

EMBROIDERY

This method is ideal for branding textile products such as bags and apparel. It involves using rayon thread to embroider the artwork into the fabric, resulting in a slightly elevated effect. This technique is highly valued for its deep and unmatched quality of branding. Additionally, it offers the convenience of a single setup charge, even when incorporating up to 12 different thread colors.

COLOURFLEX TRANSFER

Colourflex transfers utilize a CMYK+W digital printing process, making them perfect for branding apparel and fabrics. The method involves printing the artwork onto transfer paper and then applying it to the product using heat pressing. This technique allows for the creation of complex, high-definition designs, offering both full-color and approximate spot color branding options. It employs eco-friendly, water-based inks, ensuring durability and flexibility. The final result is a soft-touch, matte finish that is machine washable, enhancing the longevity and quality of the branded product.

DIRECT DIGITAL

This method involves using an inkjet machine to print directly onto the product. It is especially suitable for full-color branding, and is ideal for darker products as it can print a white layer underneath the artwork for better visibility. This technique allows for extensive print areas that reach nearly to the edges of the product. A single setup charge is applied, irrespective of the number of print colors used. It also has the capability to print variable data, such as names. Products can be promptly shipped after the printing process is completed.

SUBLIMATION PRINT

This technique is employed for branding products with a special coating or fabrics designed for sublimation. In this process, sublimation ink is first printed onto transfer paper and then heat-pressed onto the product. Since sublimation ink is a dye, there is no buildup of ink, ensuring a smooth finish. It is capable of producing vibrant, full-color images and can closely match specific spot colors. This method also allows for the inclusion of variable data, such as names. Edge-to-edge branding is possible on selected products. Regardless of the number of print colors used, only one setup charge is required.

ROTARY DIGITAL PRINT

This method involves the use of an inkjet machine that prints UV ink directly onto the product. It's highly effective for creating detailed artwork with full-color branding. Particularly suitable for large or complex full-color prints, this technique allows for vivid and bright printing results, even on darker products. There is a single setup charge, which remains the same irrespective of how many print colors are used. The products are ready for immediate shipment following the printing process.

SILICON DIGITAL PRINT

This is a CMYK+W digital branding process tailored for silicone surfaces, offering sharp, high-definition artwork. It's particularly effective for darker products as it can print a white layer beneath the artwork for enhanced clarity. The resulting branding is a durable, flexible matte finish that can withstand hand washing, without cracking or fading over time. Additionally, there's just one setup charge, regardless of how many print colors are used.

RESIN COATED FINISH

In this CMYK process, the artwork is printed onto a vinyl material featuring an adhesive backing. Following this, the branded area is covered with a crystal-clear resin, which creates a 3D effect and enhances the perceived value of the product. This method is particularly suitable for generating vivid, full-color images. It requires only a single setup charge, no matter how many print colors are involved. Additionally, it offers the capability to print variable data, like names, and allows for edge-to-edge branding within the resin-coated area.

DIGITAL PRINT

This CMYK process is proficient at printing on various media, including paper, vinyl, and magnetic materials. It excels in creating bright, full-color images and requires just one setup charge, irrespective of the number of print colors used. This method is also capable of printing variable data, like names, and offers the option for edge-to-edge branding. Moreover, it allows for customization by cutting the media into specific shapes as required.

DIGITAL LABEL

This method is tailored for branding products that are not suitable for other branding techniques. It involves printing with a digital press before applying the print to the product. This approach is excellent for creating vibrant, full-color images. It comes with the convenience of a single setup charge, regardless of the number of print colors used. Additionally, it allows for printing variable data, such as names, and provides the option for edge-to-edge branding. The prints can also be custom-cut into various shapes as needed

If you would like more information, or more guidance around what branding method is best for your logo or the product of choice, just reach out to us. Ph: 0800 784 785 Email: office@Promofactory.co.nz Click Here to download a branding methods PDF

Our Reviews..

LEARN MORE..

If you want to deliver great fundraising result, and would like to talk to us about options, simply fill in the form below, click the chat button at the bottom of this screen or call us on 0800 784 785